For prototype work, I have the boards made by OSH Park. For larger production batches, International Circuits for PCBs. I use a cheap toaster oven I bought from Ebay years ago. I made a controller called RefloLeo that controls power to the oven through a relay (Power Switchtail II) according to a specific reflow profile requirement. I Kickstarted the RefloLeo, but no longer sell these. You can build a similar product from an Arduino Leonardo with a thermocouple breakout board, and even use my open source code for this if you want.

RefloLeo:

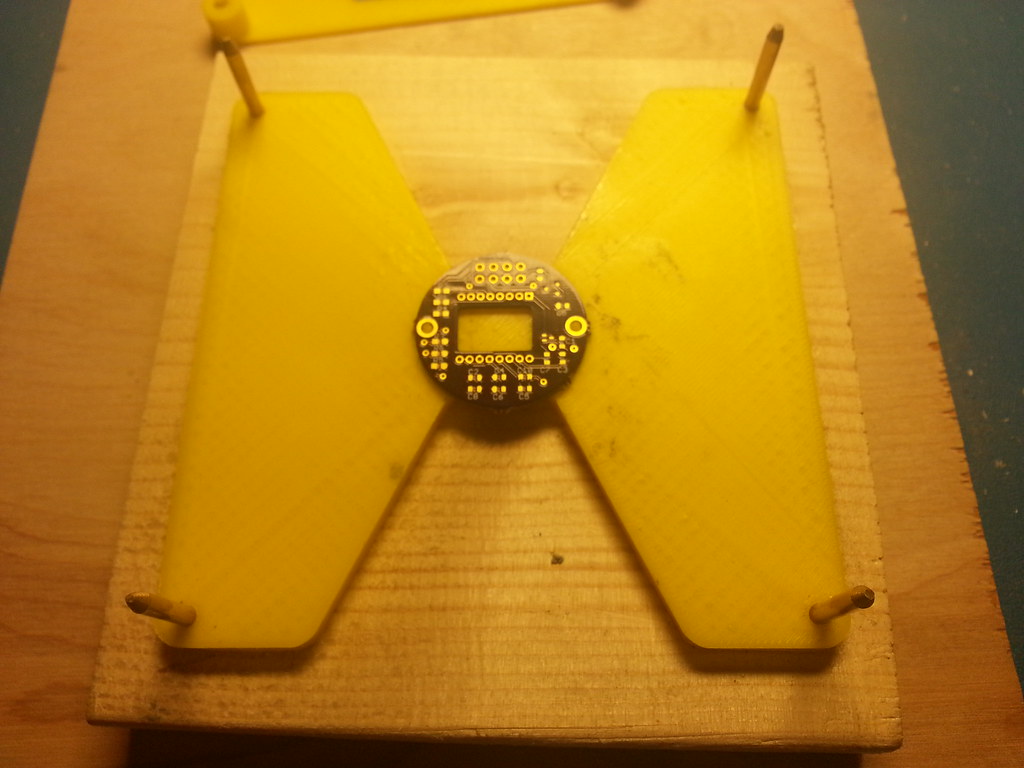

For stencils, I use a CNC router (Zenbot Mini with Wolfgang Engineering spindle). I mill from 0.003" brass sheets that I buy from McMaster-Carr.

Solder Stencil:

My CNC router:

For solder paste, using lead-free:

Kester Solder Paste, NXG33, No-Clean, SAC305

For hand-soldered parts (lead-free):

Kester Wire Solder, .025", Sn96.5 Ag3 Cu.5, #58/275, 1 lb

These days, I still use this same setup to bake boards for production every week. I can get about a dozen smaller boards in the oven at the same time and bake them. For the relatively low volume, hand assembly works well.

I place every part by hand with tweezers, so I did invest in a good set of ceramic tipped tweezers. I really like these:

http://www.techni-tool.com/758TW268

Hope that helps.

-John